Installation and Precautions

On-site Installation Precautions for Ventilation Fans

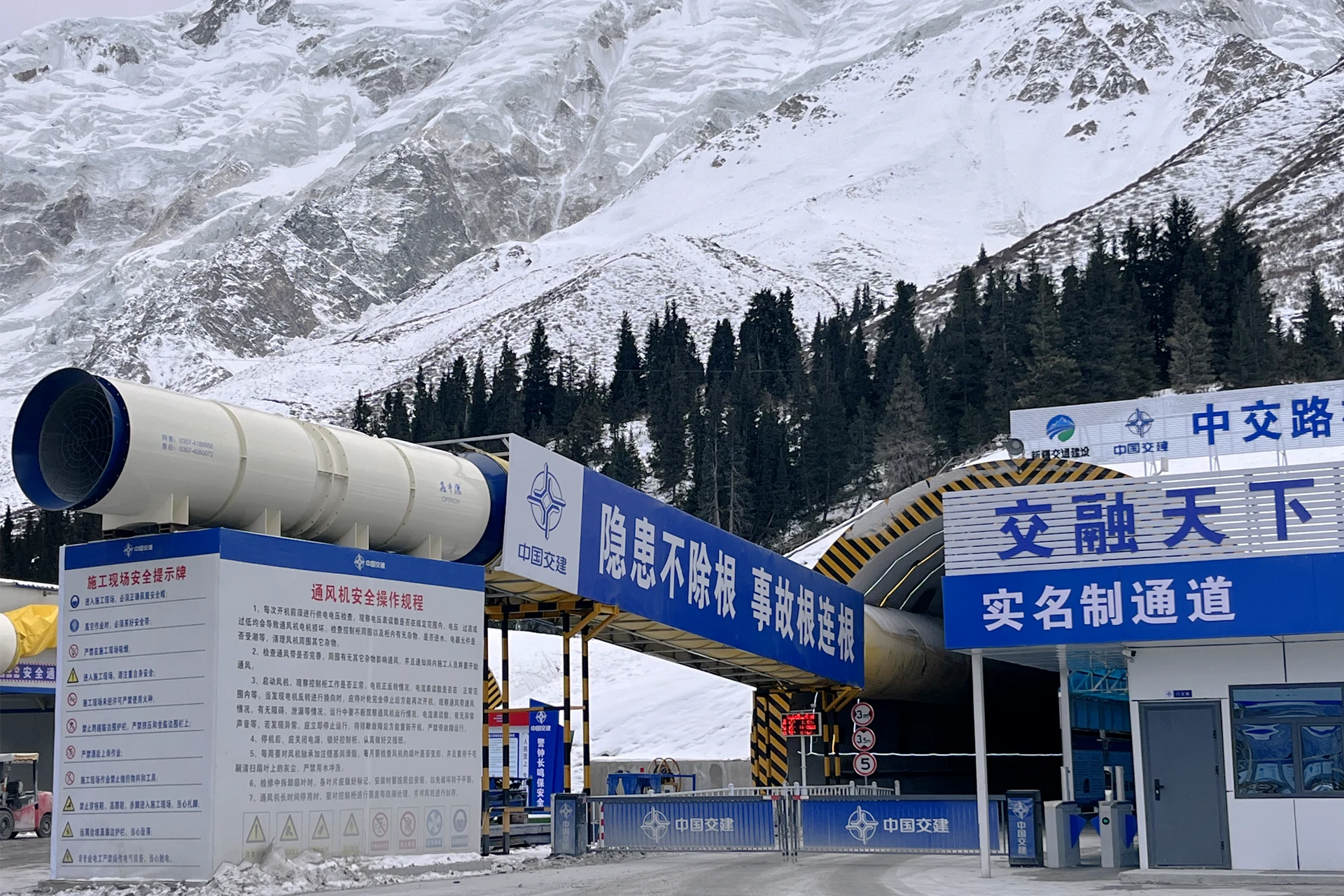

1. The fan must be firmly installed. No sundries shall be piled within 5 meters before and after the fan to avoid affecting the fan air volume and prevent foreign objects from entering the fan and damaging the blades. The fan should have overload pressure limiting and other protective devices. In case of abnormality, it can automatically shut down to play a protective role.

2. Install an iron grate at the air intake of the ventilation fan to prevent foreign objects from entering the fan and damaging the blades, and to prevent accidents that may injure people.

3. The ventilation fan operator must abide by the operating procedures to prevent mechanical accidents; do a good job of electrical protection. When the power supply is cut off, the power must be cut off. When the fan blades have not stopped rotating, do not touch the rotating parts or repair them.

4. Non-operators are strictly prohibited from turning on the power of the ventilation fan privately. Before turning on the power, the ventilation fan operator should confirm whether there are personnel repairing or extending the air duct in front to prevent injury from the air supply.

5. When various vehicles and personnel are traveling in the tunnel, they should maintain a certain distance from the fan and air duct, and pay attention to protecting the ventilation pipeline.

6. Ventilation workers must wear safety helmets when entering the tunnel. If any air leakage or other faults are found in the ventilation system, they should immediately notify the relevant personnel for handling.

7. When extending, replacing, or repairing the air duct, the personnel should do a good job of protecting the tunnel transportation vehicles to avoid falling accidents.

8. The fan base frame and air duct load-bearing ropes should be checked frequently to prevent breakage due to rust or other reasons, which may affect ventilation.

Ventilation Fan Operating Procedures

1. Before starting the machine, check whether there are any foreign objects inside the fan. If there are any foreign objects, they should be cleaned up in time.

2. Check whether the voltage is normal.

3. Turn on the machine by pressing the start button, listen to whether the fan sound is normal, and whether there is any abnormal noise. If there is any abnormal noise, stop the machine immediately and check.

4. The on-site electrician routinely checks whether all electrical components are normal, and whether the various connection terminals, wire ferrules, and connection screws are loose.

5. Add lubricating oil on time. Add oil every 500 hours of operation. Add 50-60 grams to each bearing each time. (Some fans do not have oil filling holes, they are sealed bearings, and do not need to add grease, maintenance-free bearings have a lifespan of more than 20,000 hours);

Note:

(1) New fans have been filled with grease, do not add grease again, wait until the running time before adding;

(2) Grease Model: Molybdenum disulfide or No. 3 lithium-based grease.